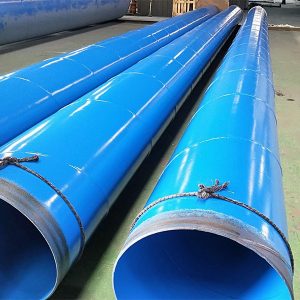

Plastic-coated anticorrosive pipe is based on ordinary carbon steel pipe, and the inner and outer walls of the pipe are coated with thermoplastics with excellent chemical stability. It is not only a high-performance anticorrosive pipeline, but also the first choice for energy-saving and environmentally friendly pipeline products promoted by the state. Brief Introduction of Plastic Coated Steel Pipe for Water Supply and Drainage

With the development of chemical industry, higher performance requirements have been put forward for chemical pipelines. Anti-corrosion coated steel pipe can fully meet the transport of fluid media in the chemical industry. The pipeline has excellent anti-corrosion performance, and its comprehensive performance is among the best in the pipeline, exceeding similar performance. The product is several times the best performance of anticorrosion pipes in the chemical industry so far.

Plastic-coated composite pipe for water supply has the advantages of high mechanical strength, non-shedding coating, resistance to chemical corrosion, antibacterial, high cost performance and so on.

Common colors: black, gray, blue, red, white, green;

Coating thickness: PE (modified polyethylene) coating thickness is 400um-1000um, EP (epoxy resin) coating thickness is 100um-400um;

Coating method: PE (polyethylene) hot dip EP, (epoxy resin) internal and external spraying;

Product Specification: DN15-DN1660;

Ambient temperature: -30 °C to 120 °C;

Connection: thread (DN15-DN100), groove (DN65-DN400), flange (suitable for any diameter), welding, bimetal connection, socket, pipe joint, sealed connection, etc.

Application area

1, circulating water system in various forms (civil circulating water, industrial circulating water), excellent performance, anti-corrosion life of up to 50 years.

2. Fire water supply system.

3, all kinds of building water supply and drainage transportation (especially suitable for hotels, hotels, high-end residential areas of hot and cold water system).

4, a variety of chemical fluid transport (acid, alkali, salt corrosion).

5, wire and cable underground pipelines and through the pipeline.

6, mine, mine ventilation pipes, water supply and drainage pipes.